Axiome reveals its new technical center

In 2018, Axiome has developed robotic solutions for process validation and reveals today its new technical center.

In consultation with its customers and thanks to the commitment of its collaborators, Axiome has developed several state-of-the-art robotic cells. These machines carry out tests and pre-series under real conditions, in order to validate the processes proposed by Axiome, with a view to future industrialization.

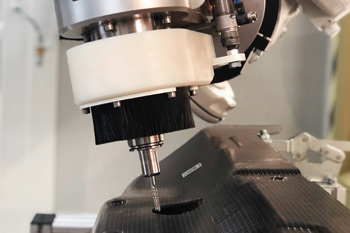

This technical center has three cells. A mechanical milling and deburring cell. This machine is equipped with a latest generation ABB IRB 6620 robot, a high-speed spindle with an automatic tool changer and dust extraction. The force sensor at the end of this robot analyses the data in real time, and adapts the trajectories if necessary.

A fluid jet deburring cell. This machine incorporates a Stäubli robot, offering the possibility of working in immersion for fluid jet deburring of 3D parts of various materials. Connected to a triplex pump of 2,500 bars, 15 l/min, or to a pump of 3,800 bars, 2.5 l/min, it can work with water or oil.

A water jet or abrasive cutting cell equipped with a suspended Stäubli RX160 robot, covering a working volume of up to 2,000 x 2,000 x 800 mm. This robot carries out tests or pre-series of cutting 3D parts of very varied materials (composites, stainless steel, titanium...).

"Axiome has developed several state-of-the-art robotic cells"

All these machines, coupled with robotic simulation equipment, make it possible to validate the quality obtained, the process speeds, the tools, the accessibility of the areas to be treated and the cycle time of future series machines.

Machine Production, 01/10/18