CLEANING MACHINES

Cryogenics

Cryogenics is a cleaning technology used in many industries.

The cleaning is done under the combined effect of :

- The Mechanical impact of ice on the support

- The thermal shock associated

- The breath due to the phenomenon of sublimation of the ice

This avoids the use of solvents, there is no chemical attack on the support to be cleaned, nor waste linked to the cleaning means, and this process can be robotized for the automotive or aeronautical industries for example.

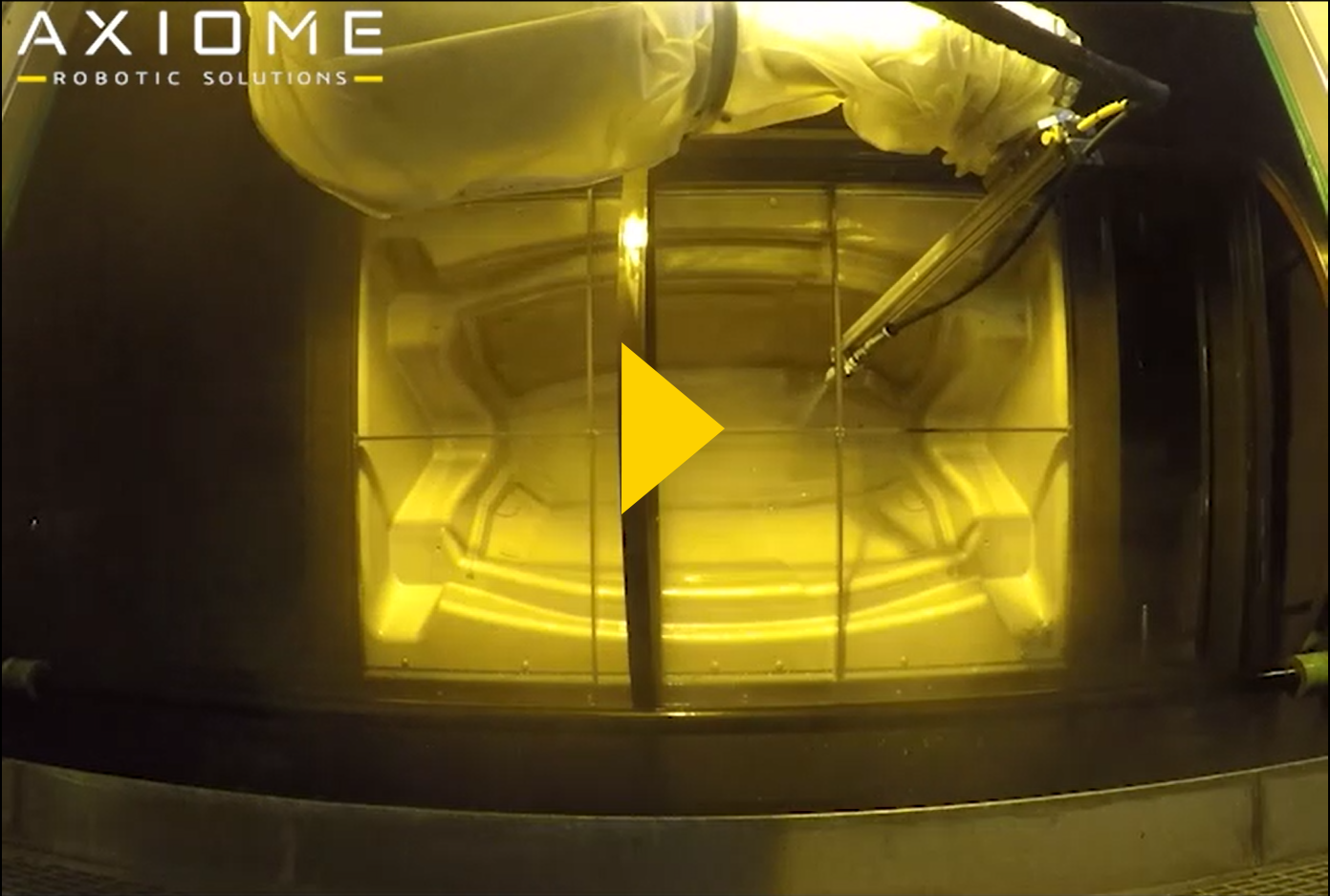

Water jet stripping

The stripping process is well known. It can be industrialized by integrating one or more spray nozzles on a polyarticulated robot.

The trajectories can then be adapted to complex surfaces with movements enabling cleaning.

The robot (s) can also be integrated on linear axes in order to process large parts.

Applications: cleaning concrete formwork or railway equipment, for example.

Flushing

The principle of flushing, as its name suggests, is the process of cleaning by causing large quantities of water to pass through a part, producing a swirling effect if possible. In this process, the pressure is not decisive (although not negligible) unlike the principle of water jet cutting or deburring by fluid jet.

Flushing is based on high water velocities, the regime must be as turbulent as possible - non-laminar. On our machines, a high flow rate is defined for each part. One or more reversal of the direction of flow contributes significantly to the efficiency of cleaning and to achieving the desired cleanliness class. The level of flow and pressure used influence the type of particles discharged. This cleaning principle is regularly used in the automobile.

Robotic skills and expertise

ROBOTIZATION

The robotization of these processes ensures :

- High repeatability

- Total security for operators

- Containment of dust, noise, vapours...

- A minimum waste rate

- Execution in an optimized cycle time

stripping