FLUID JET DEBURRING MACHINES

AXIOME fluid jet deburring machines

Our fluid jet deburring machines are specially designed to remove the burrs quickly, efficiently and accurately. Thanks to our innovative technology, we can achieve high-quality finishes while reducing costs and increasing your productivity.

The instantaneous impact of water or oil is used to eliminate the burrs produces during machining, while maintaining the geometry of the parts, without any thermal effect, and with a cleaning effect. This process can bu used for a part displacement or nozzle displacement.

Very High Pressure deburring, by water or oil jet is used to deburr various materials:

- Aluminium alloy

- Copper

- Brass

- Plastic derivatives

- Steel

- Etc...

The deburring machines are equipped with a Triplex pump (flow rate up to 60l/min) and a fixed or rotating jet head. Ultra high pressure deburring is used for relatively hard materials such as stainless steel, hardened steel... The pressure is 1,000 to 3,500 bar. It is the pressure of the fluid that is then privileged over the flow rate.

Deburring applications

Large and very large deburring series

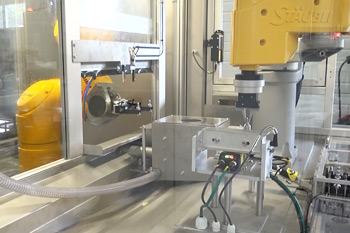

AXIOME offers deburring solutions for large production runs particularly in the automotive idustry. Our single and dual robot machines can be adapted to the requirements of each customer, ensuring optimium efficiency. Fluid jet deburring eliminates burrs on a wide range of materials ensuring a high quality finish while preserving part integrity. Our systems can be intagrated with advanced vision processes, ensuring accurate management of part traceability.

Deburring of brass and aluminium parts

The deburring of brass and aluminium parts is particularly used in the automotive, watchmaking and aeronautic industries. With the possibility of using single jet nozzles or rotating heads with multi-nozzles, our innovative machines guarantee precise removal of chippings and burrs. All this while ensuring impeccable finishing of parts, whether small complex parts or large series.

Vehicle injector parts

A specific AXIOME development is the automated deburring of injection-moulded parts for cars. This guarantees high repeatability and a consistent quality. Our machines offer a cost effective alternative to traditional methods, reducing labour costs and production downtime. Thanks to the use of robots, our systems are flexible and easily adaptable to various configurations, ensuring maximum efficiency for each customer.

Robotic skills and expertise

WATERJET DEBURRING

BENEFITS OF DEBURRING

- Accessibility in difficult arreas

- Small diameters

- No thermal effects

- Consistency of the result

- Cleanliness of deburred parts

- Absence of marks and cracks

- Respect for the environment

- Fast and precise removal of burrs

- Flexibiliy for different types of parts and materials

OIL DEBURRING