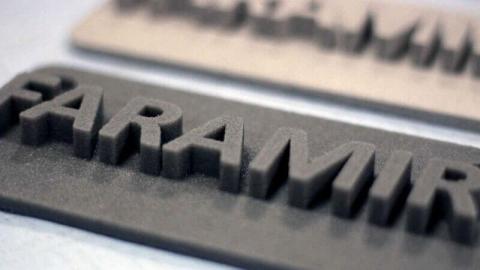

FARAMIR project

As part of the FARAMIR project, the IRT Jules Verne is acquiring new state-of-the-art equipment for the production of toolings by additive manufacturing. Now installed at Loiretech, this new high-capacity machine marks a major milestone for the project.

The project

The project had already recorded a major milestone with the installation in January 2019 at IRT Jules Verne of VOXELJET VX200 equipment for the manufacture of the first impregnated 3D specimens.

Launched in May 2018 for a period of 3 years, the FARAMIR project brings together IRT Jules Verne, Loiretech and AXIOME and has a budget of €1.63 million. This is the first project developed as part of the Accès PME scheme, supported by the EMC2 cluster to carry out projects within the IRT Jules Verne. With this program, the IRT Jules Verne intends to strengthen its relations with innovative companies in the West of France that design processes for the future of factories, by supporting their skills development and offering them the possibility of integrating shorter research systems and facilitating lean project assembly processes.

The FARAMIR project aims to develop a mineral-filled additive manufacturing process to produce functional parts at optimized costs. After the installation of a small capacity machine at the IRT Jules Verne, the first parts resulting from this technology were exhibited at the world composites fair, the JEC World in 2019.

The new ExOne equipment allows the manufacture of tools with characteristics equivalent to tools made from machinable boards, with the aim of manufacturing complex-shaped parts in a single step. In addition, the IRT Jules Verne will work on the change of scale in the development of new processes, precision and repeatability.

Interview

We asked three questions to Rémi Chauveau, Research & Innovation Engineer at Loiretech, involved in the FARAMIR project.

What is this new ExOne machine for?

This large-capacity machine will make it possible to improve the mechanical and geometric properties of the tools and to develop a process for impregnating printed tools, an important step implemented by the teams of the IRT Jules Verne. It marks the last phase of the project towards the production of the final demonstrator, namely a tooling prototype which will be tested under conditions of use.

In addition, within the framework of the FARAMIR project, it is a question of eliminating the consuming stages in terms of time and cost.

Finally, the project is part of the corporate social responsibility (CSR) approach by limiting the environmental impact of the manufacturing cycle.

What will this new equipment bring to the project?

This state-of-the-art equipment will make it possible to roll out a test plan in order to produce the expected demonstrator. The objective is first to seek to improve the mechanical and geometric properties of tools, to then develop a process for impregnating printed tools to achieve mechanical performance similar to that of current tools. Finally, the capitalization of the results obtained will be used to produce a tool prototype for the functional tests, a test which will be carried out by the third partner of the project, Axiome.

What will this work bring to Loiretech?

From Loiretech's point of view, this equipment will revolutionize the way of thinking and producing. The possibilities in terms of design are increased, and it will thus be possible to integrate directly into our tools functions that were until now, carried out in a more traditional way.

IRT Jules Verne, 14/04/2020