MILLING MACHINES

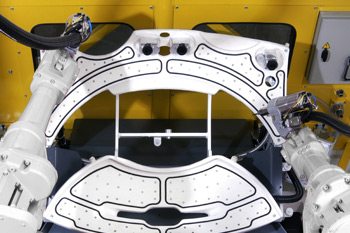

Robotic milling machines

AXIOME designs and manufactures robotic machines for cutting parts by milling. It is possible to cut different types of parts and materials. Robotic milling consists of integrating a high-frequency milling spindle into a polyarticulated robot. High-speed milling technology is designed for a very wide range of materials and can be implemented in cells with one or more robots. AXIOME integrates the necessary peripherals to adapt the machines to the production needs of its customers, thus improving working conditions:

- Dust and chip containment

- Noise reduction

- Automatic evacuation of falls

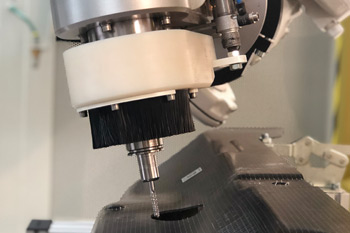

The average cutting speeds are between 80 and 250 mm/second, with spindles ranging from 0.5 to 10kw. The tool rotation speeds are in the range of 15,000 to 40,000 rpm, and many tools can be used:

AXIOME uses the milling cutters best suited to your project, in order to guarantee an irreproachable cutting quality and a long life of your milling bits.

Milling and machining applications

Cutting of high speed parts

AXIOME designs machines with single or double robots, especially for the automotive sector, and adapts according to the cutting pace required.

Drilling

Drilling machine are used for various materials: aluminium, plastic, composites. It is a perfect solution for microperforation of acoustic materials.

Cutting of carbon/composite parts

AXIOME machines offer the possibility of using multiple tools. AXIOME has developed the deburring of composites using compliant tools. The implementation of milling for composite materials takes into account the constraints of dust, chips, etc....

Resin and fibreglass parts

AXIOME's milling machines are designed to trim parts for ships or motorhome interior. Because some parts may be large, robots can be upgraded with external axes: turntable, linear rails....

Airbag weakening

A specific AXIOME development allows airbag weakening to be applied to injected parts with high precision. These machines are a cost effective alternative to other attenuation processes.

Natural fiber parts

AXIOME machines and tools are a great option to cut parts made of natural fibre materials: Natural Fiber Poly Propylene (NFPP)

Robotic skills and expertise

MILLING PROCESS

BENEFITS OF MILLING

- A high cutting quality

- A high speed cutting

- A depth control

- A flexible installation

- A quick return on investment

- An automatic changing tool

3 robotis MILLING PROCESS