Plastic and composite additive manufacturing

AXIOME robotic 3D printing machines

The technology used in our applications is Fused Deposition Modeling (FDM). The granules are melted in an extruder, which deposits them in filament form, layer by layer, until a complete product is obtained. The granules can be made of plastics such as PLA, ABS, TPE, TPU, PVA, PC, PET, PETG, NYLON, PEEK, PEKK, PAEK or composites containing carbon or glass fiber.

Our expertise

AXIOME partners with head manufacturers to offer customised turnkey solutions.

- Complete design of the cell and its peripherals.

- Taking account of the customer's specific needs and industrial environment.

- Validation and transfer to the customer site.

- Production monitoring.

The AGIL range of additive manufacturing machines developed by AXIOME

Version One

This machine is composed of a 6-axis robot on a plateform, integrating the head and its peripherals, all in a secure enclosure. This configuration allows the printing of small, simple 3D parts.

Version Flex

In this configuration, the machine is made up of a 6-axis robot on a plateform, integrating the head and the peripherals. The robot works on a positioner with 2 additional rotation axes in order to have total flexibility.

Version Large

In this configuration, the machine is made up of a 6-axis robot on a plateform, integrating the head and the peripherals. The robot is placed on a linear axis to print very large parts.

ADDITIVE MANUFACTURING APPLICATION EXAMPLES

Additive manufacturing use cases

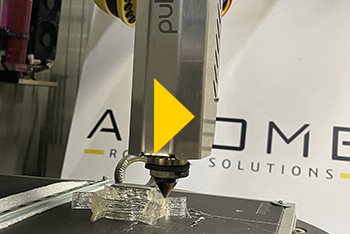

Detail of the head of an additive manufacturing machine

Additive manufacturing use cases

Detail of the head of an additive manufacturing machine

Composite deposition by extrusion

FDM (Fused Deposition Modeling) technology is an Additive Manufacturing process that works with granules. They are melted and extruded in liquid form, to be superimposed precisely, layer by layer.

The possibilities for creating objects are immense. It is possible to create small customised objects, complex high-performance parts and sophisticated designs, as well as large-scale parts.

Choosing an additive manufacturing machine

0% MATERIAL waste

The FDM (Fused Deposition Modeling) deposition process allows the granulate to be melted and deposited accurately, using 100% of the material unlike other processes which have up to 50% waste material that cannot be recycled.

CoNTROLLED PROCESS

The FDM (Fused Deposition Modeling) extrusion nozzle provides a precise heating zone that limits heat transfer to the lower layers of the part. This optimises the internal structure of the object.